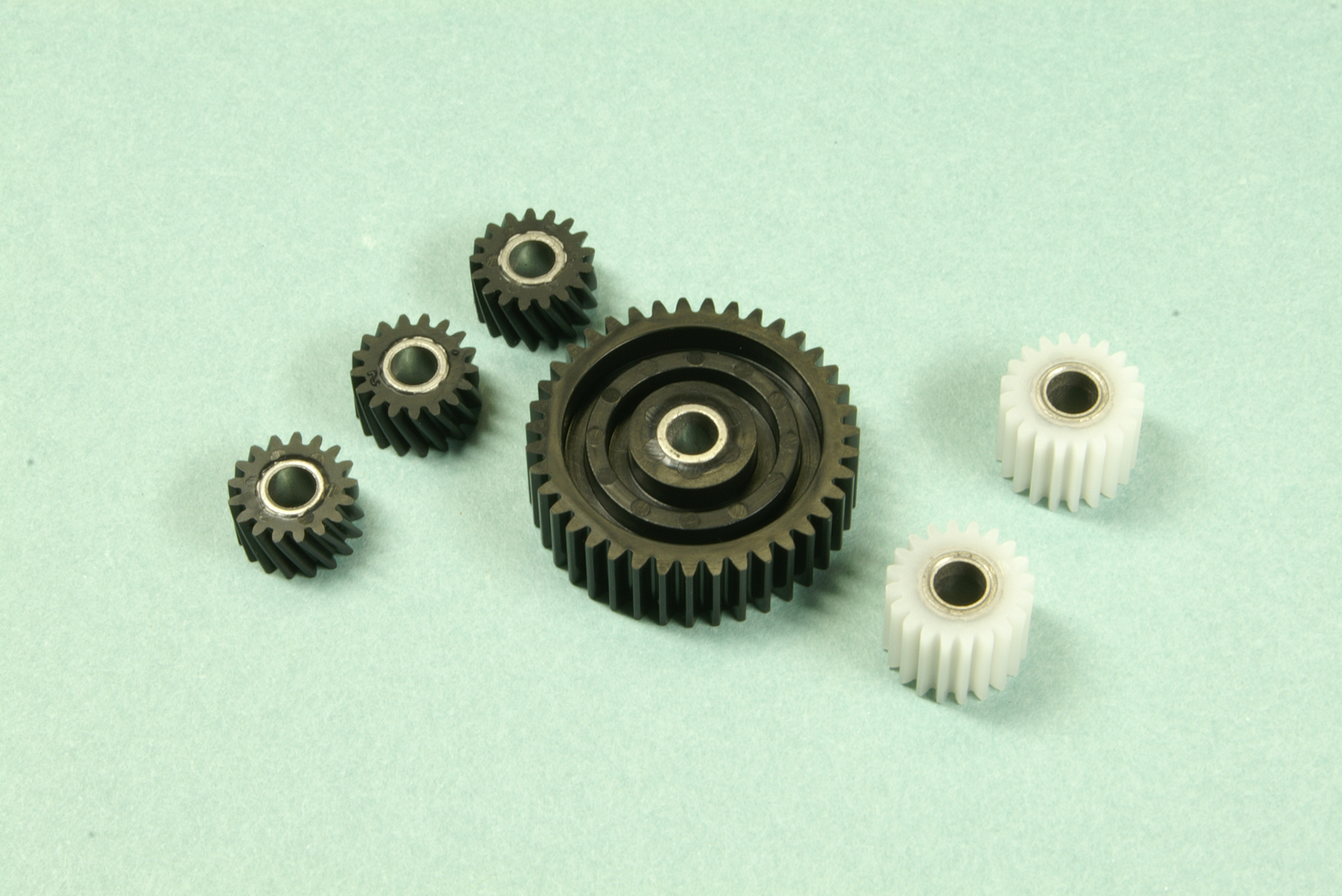

Metal substitute value engineering (VE)

Rewriting conventional wisdom!

Strengths in metal substitute VE

We have realized reliable mass production molding on a micron scale,with super engineering plastic materials that are extremely difficult to mold.

We have made a number of VE achievements with metal substitutes to meet the ever-increasing needs for high functionality and weight reduction in cutting-edge product applications.

High functionality

Utilizing the excellent properties of super engineering plastics, we have achieved weight reduction in parts, as well as metal substitute value engineering, including heat resistance, impact resistance, abrasion resistance, chemical resistance, and noise reduction

High precision

For example...

- Gears: We have achieved stable mass production of gears at JIS-1 grade and JGMA-0 grade

- Bearings: We have achieved mass production with outer diameter φ20 mm, inner diameter φ5 mm, material POM, and coaxiality of 5 μm.

Materials

PEEK, PAI, PPS, PBI, PES, PPSU, PEI, PSU, etc.

Various super engineering plastics, engineering plastics in general

Initiatives for quality and development

In addition to various measuring equipment, we have various gear development equipment such as mesh durability testers, gear strength testers, and tensile strength testers, so we can offer one-stop service, from basic testing to implementation evaluation with our fully equipped facilities.